Tom Kubinski Mary Albers www.sextonprinting.com

|

May 2007 TK's Korner

Digital

Printing/ Variable Data or Business Development

This issue of TK's Korner

explores digital printing-and how it is revolutionizing the way that

businesses reach out to customers and how they can really develop their

business or marketing strategies. It looks at how digital printing

differs from conventional offset printing and why it's fueling

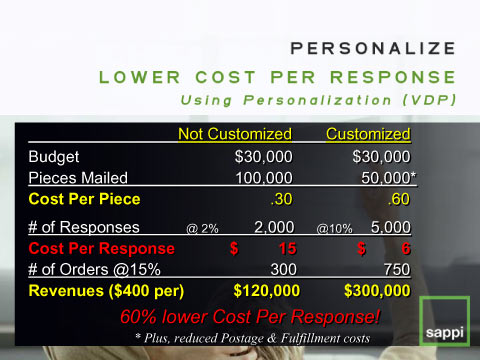

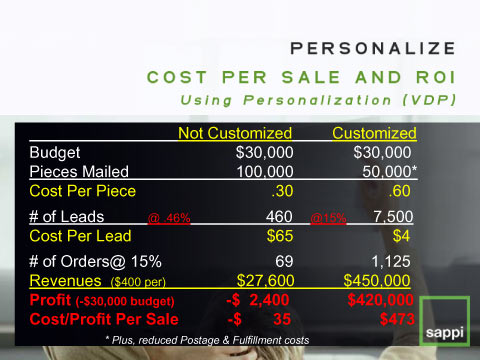

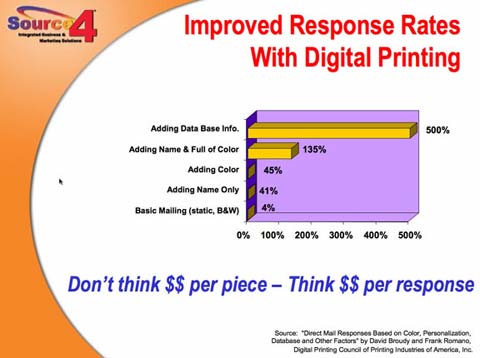

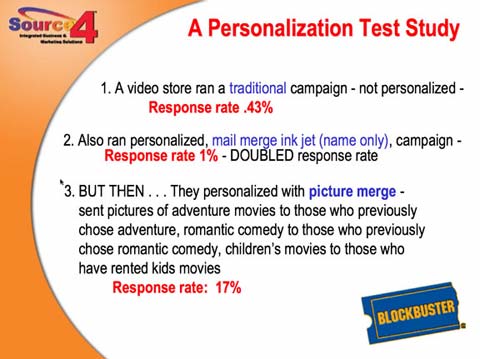

the growth of One-to One Marketing using Variable Data Printing or VDP. "Lower Cost Per Response" "Cost Per Sale and ROI" "Improved Response Rates with Digital Printing" "Integrated Direct Marketing Programs Have Their "Value"" "A Personalization Test Study" Digital technology is changing the face of printing. It's making printing faster, easier to produce, more flexible and reducing the need to produce/hold huge inventories. It is transforming it from a mass medium that is a spray and pray one into a customized one-to-one marketing one. Blending digital printing technology with electronic customer databases, VDP allows you to create personalized promotions that not only call each member of your audience by name, but also reflect their personal characteristics, lifestyles or tastes. VDP provides a powerful new tool to win the attention of your audience, one person at a time, and frequently, capture higher sales, lower your cost per sale/response and increase your ROI. Variable Data Printing is a form of on-demand printing in which elements such as text, graphics and images may be changed from one printed piece to the next without stopping or slowing down the press, using information from a database. This issue won't make you an expert on the subject over night, it will show you the potential of digital technology using VDP-and how it can help you reach your communications objectives. What's behind the change is the marriage of reliable, high-speed digital printing and sophisticated database software, which combine to produce One-to-One Marketing using VDP for full color documents that look and feel comparable to conventional offset printing. There are two main operational modes to VDP. The other methodology, is to combine the static and variable elements prior to printing using specialized VDP software applications. These applications produce an optimized print stream, such as PostScript, which organize the print stream efficiently so that the static elements are only processed once by the RIP. Digital Defined: Digital technology permits quick turnaround, immediate finishing, no wait time for drying and allows for low-quantity print runs. Books and brochures can be printed on-demand, as they are ordered, eliminating the need to print large quantities of materials and then hold them in inventory. Digital Goes Personal: The returns: Others say, variable printing vary from double the normal return on the first level to 10-15 times the return on fully variable. It depends on the data and the relevancy but it is very effective tool to increase your ROI on your mailings. So even higher per-page costs, variable data printing can make for a lower cost per response-and higher returns form your communications investments.

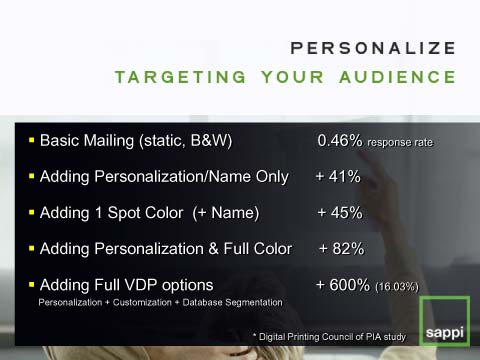

How to Increase Response:

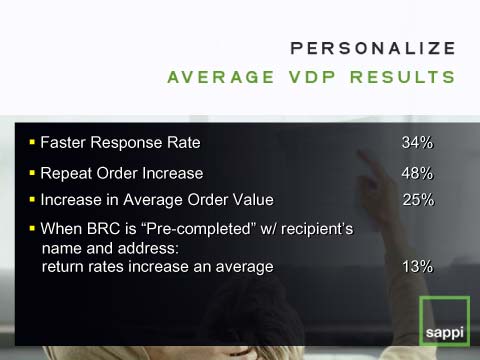

NOTE: +600% (this equates up to 16% total)=Full variable data: personalization, customization, database segmentation. IE; specific targets, smaller qty, more opportunities to respond. Variable Data Results:

NOTE when BRC is "pre-completed" with recipients name & address, return rate increases 13%. Personalization Drives Response(2004 study)

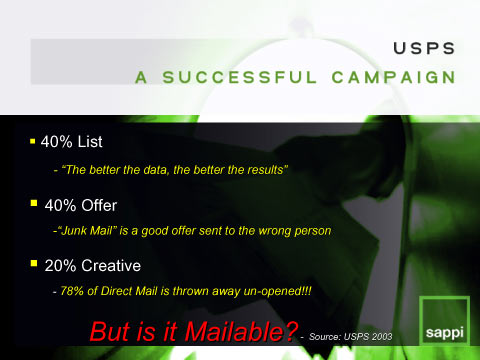

NOTE it's not the quantity that is sent out, but the number of responses you get back that matters. A Successful Campaign NOTE: One factor that has been left out, is timing. It is critical that you time your programs based on what is going on with your business, cycles of purchasing, world events etc. Data Base is the most important lever:

NOTE: 18% of Americans

relocate, 2% of your list moves monthly Mail list hygiene:

There are actually several levels of variable printing:

All of these are done by having a base design programmed to show what will change and then a database that will actually drive the changes of the fields that will change. Five levels of complexity:

While VDP opens new options in communications, it's best to proceed carefully. You and your printer should match the equipment to the demands of the jobÑeach type of equipment has its own weakness and strengths. You want to make sure that the printers you work with are experienced in handling both the printing technology and the information systems needed to drive it. When starting out, it's best to keep things both simple and subtle. While it's possible to personalize virtually every aspect of a publication, large numbers of permutations become more difficult to manageÑsimply assembling all of the images and reviewing all the options can be challenging. It also appears that the days of boldly calling attention to personalized information are coming to an end. Today, many of the best examples seamlessly weave personalization into the project without flaunting it. After all, the goal is to reach customers, not to showcase your technical prowess. Before you Decide to go variable, however, it's good to keep a few things in mind:

Biggest difference, most systems rely on toners, not inks. After they are applied, toners are typically baked onto the surface of the paper at a high temperature. Only a problem when using conventional shells. IE running a large conventional shell program and then coming back with a digital imprint over a conventionally printed area having color such as a tinted background. The conventional inks could liquefy causing a smeared type look. Again a test run doing this is a good idea. Best case, imprint onto a conventional shell on the white paper surface only. 1) For this reason, many

experts recommend against using toner-based printing systems to print letterhead stationary-feeding it through a high-heat laser printer might cause your

name or logo to lose definition. 2) Compared to conventional inks, toner is also somewhat more likely to crack when folded. So, it's important to avoid large floods of color or heavy toner coverage on the folds. Using perfect binding rather than saddle stitching will also help reduce cracking. 3) Dry toner-based systems typically cannot print at the high resolutions available with the best offset printing, so the use of extremely fine screens should be avoided. 4) The electrostatic charge used to attract the toner often varies in strength across the sheet, which can be make it difficult to control gradations. 5) Since few system allow for the use of spot colors, it can be difficult to match corporate colors or to print metallic inks. 6) Keep in mind that what you see on the monitor is NOT what you'll see on pressÑthe colors on screen are inherently more vibrant and encompass more of the entire spectrum. Toner-Based-digital Pritning Systems; Xerographic Systems: Laser Printing Systems:

Ink Jet Based:

Hybrid Technologies: Digital Papers: It's especially important to control the moisture content of the paper before and during printing. Digital paper typically contains less moisture than conventional offset papers, so there's less moisture to evaporate through the printed image when the toners are fused by heat. Both temperature and moisture content are critical for the paper to receive the correct electrostatic charge during digital printing. Generally it is best to avoid papers with heavy textures, since the toner may not adhere evenly or might rub off on the high spots. Always make sure that the paper's basis weight matches the specifications of the equipment that will be used to print the project. Food for Thought; Other issues of TK's Korner

that may be of interest: More info listed below that you may find of interest: Case Studies

I hope this issue has been helpful in letting you know more about Digital Printing, what options are available to you and how to increase your response rates. If you would like more information for your next printed project, to see some of the really cool samples I have or regarding this article, please give Tom Kubinski a call @ 651-255-1225.

If you would like to join me on one of our upcoming tours, if there is something that you would like me to address, or if you know of someone who might like to receive TK's Korner, please let me know via e-mail at tkubinski@sextonprinting.com or phone. Take care and have a great day.

Successfully, |